Epoxy & Carbon Fibre Repair Composites

We offer advanced composite repair solutions including leak sealing, substrate loss rebuilding, cold plate bonding and composite pipe-wraps that are designed to provide rapid, reliable, and cost effective alternatives to traditional solutions such as welding and replacement.

Cold Plate Bonding

Our composite repair solutions provide an excellent alternative to welding for rapid plate bonding onto steel. By using high performance epoxy products with proven capabilities, we ensure strong, durable bonds without the need for heat processes that introduce safety risks and cause damage to adjacent materials such as internal linings, reducing downtime and eliminating associated risks.

Leak Repair with Carbon Fibre Wraps and Epoxy Composites

We provide carbon fibre and epoxy wrap systems that are engineered for rapid leak repairs and reliable structural integrity repairs. This technology provides a quick and effective solution, allowing for immediate containment of leaks and reinforcement of structures, avoiding the lengthy downtime associated with traditional repair and replacement methods. Our composite wrap solutions can be designed to ASME PCC-2 & ISO 24817 standards and works can often be completed without need for shutdown or isolation due to their low risk nature.

Metal Loss Repair and Rebuilding

For cases of corrosion where welding is impractical, our epoxy composite solutions can be applied to rebuild substrate thickness without the need for isolation of assets or hot works safety considerations. Metal loss rebuilding can be used to provide an original profile to allow for optimum operational performance or reinstallation of componentry requiring accurate original geometry.

Our in-house AMPP (previously NACE) certified coating inspectors oversee our strict quality requirements using our ISO 9001 certified quality management systems. With an extensive range of testing equipment and qualified inspectors, we excel in projects where strict adherence to specifications is imperative and can assist in pre-execution activities including condition assessments, specification development and project management.

Application Examples

Intercooler resurfacing

Rebuilding of a significantly corroded mine intercooler using rapid metal filled epoxy composite during a very tight shutdown outage where welding would not have been achievable in the allowable timeframe.

Storage tank leak repairs

Rapid repair of storage tank’s leaks by cold plate bonding 5mm steel plates using an epoxy composite solution that required no hot works risks or considerations.

Plate bonding

Plate bonding over through wall defects on a digester tank where welding would have been impractical due to adjacent combustible insulation.

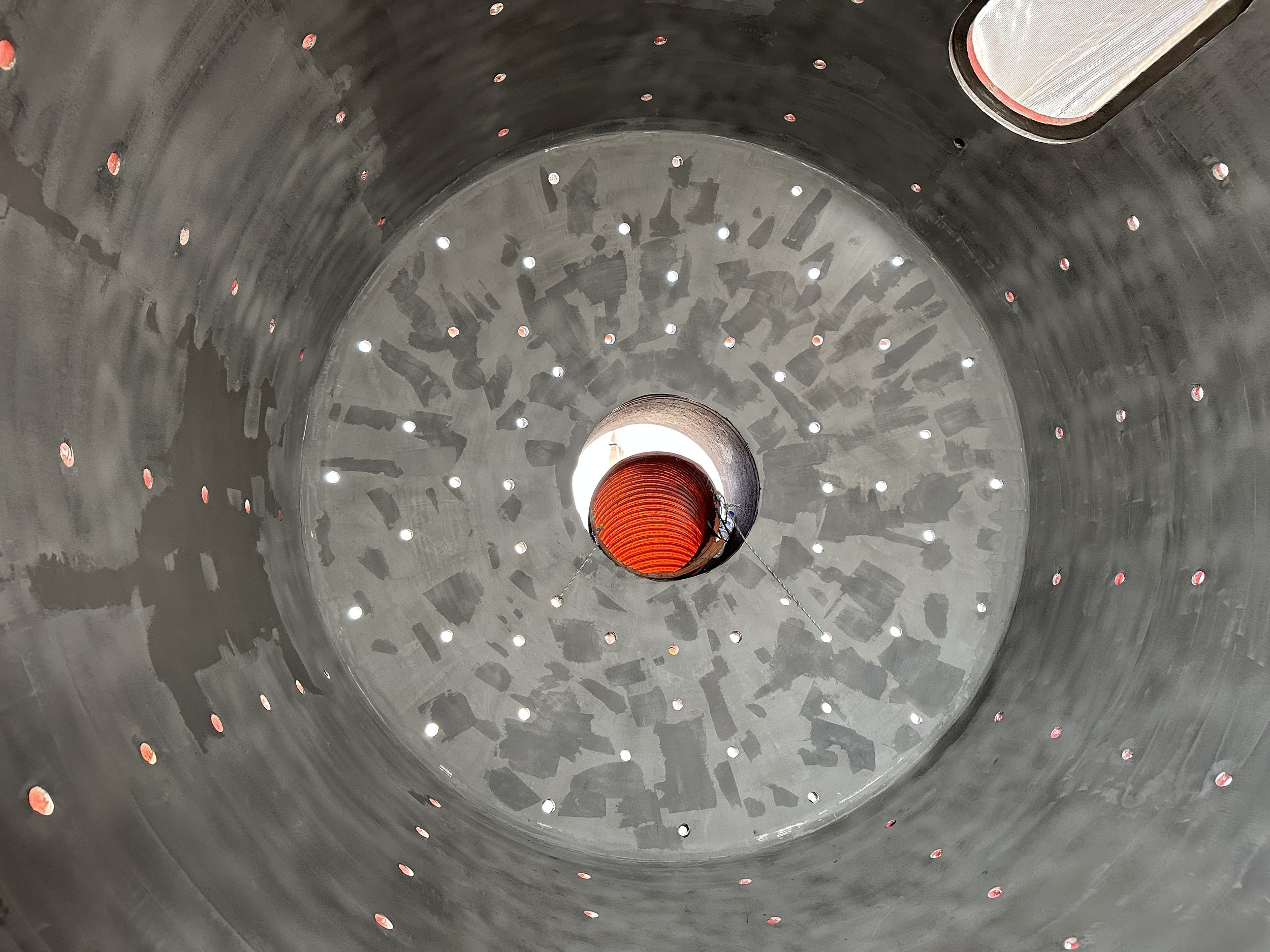

Ball mill resurfacing

Resurfacing of a heavily pitted ball mill using a ceramic carbide composite material for extreme wear resistance.

Transformer leak repairs

Live leak repairs on a high voltage transformer’s gaskets without the need for draining of oils or any other hot works considerations.

Flange face reforming

Refacing of heavily pitted stainless steel flange faces using an epoxy composite solution for rapid repair and reinstallation.